Label

All

0

Clear all filters

🌷 Spring savings – save 25% on ckbk Premium Membership with code SPRING25

Basic Bread Vocabulary and Processes

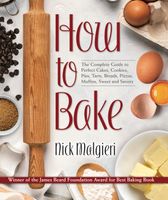

Appears in

Published 1995

What follows are the basic steps of breadmaking, along with definitions and explanations of the procedures.

- MEASURING: Accurately measuring all ingredients.

- MIXING: Forming a dough from the ingredients, either by hand or by machine. In the straight dough or one-step dough method, all the ingredients are combined and mixed on low speed for approximately 10 minutes or until the dough is smooth and elastic. In the sponge or two-step dough method, part of the flour, all or part of the liquid, and all or part of the yeast are combined to make a sponge that is allowed to ferment before the remaining ingredients are added.

- FERMENTATION: Allowing the mixed dough to rise. Usually doughs are allowed to double in bulk (100 percent increase in volume at this stage). Fermentation usually occurs at room temperature.

- DEFLATION: Punching the dough down and knocking the accumulated gases from it before beginning the shaping process. For some doughs, fermentation and deflation are repeated several times to develop flavor and texture before the dough is ready to be shaped.

- RETARDING: Refrigerating a dough or sponge so that it ferments very slowly, or the fermentation process is interrupted.

- DIVIDING: Cutting the dough into the required number of pieces for the breads to be made from it.

- ROUNDING: Shaping the pieces of dough into balls so that each piece of dough presents a smooth outer skin, which will become the crust.

- BENCH PROOFING: Allowing the rounded pieces of dough to rest or recover briefly after rounding. Note: In the case of small goods, such as rolls, the large, rounded, and bench-proofed pieces of dough are further divided and rounded into smaller pieces.

- SHAPING: Forming the bench-proofed dough into the correct shape for the loaf.

- WASHING: Brushing or spraying the shaped goods with egg wash, raw or cooked starch wash, or another liquid. This process may be performed several times or only before or after baking.

- PANNING: Placing the shaped goods on sheets or in pans. Sufficient room must be left between items on the same sheet, or in a loaf pan, to allow each to expand up to three times larger than the shaped size.

- FINAL RISING: The final fermentation before baking. This often takes place in a proofer or proof box, in which both temperature and humidity are high to provide a beneficial environment for the fermentation. If you are letting loaves rise at room temperature, it is best to cover them with plastic wrap that has been buttered or oiled to prevent sticking.

- BAKING: During the initial stage of baking, air bubbles formed during fermentation expand, causing the goods to increase dramatically in volume. Before the internal temperature of the dough reaches 150 degrees, fermentation continues in a greatly accelerated manner, also causing the volume to increase. The combination of these two increases is known as oven spring.

- DETERMINING DONENESS: Most yeast-risen goods test done when the bottom is tapped and the interior sounds hollow. A more accurate test is to use an instant-read thermometer; it should read about 210 degrees.

- COOLING: All yeast-risen goods must be thoroughly cooled at room temperature, usually on a rack so air can circulate around all sides.

- STORING: Store crusty breads, uncovered, at room temperature, the day they are baked; the crust will keep them fresh for a short time. Otherwise, wrap in plastic and freeze. Delicate goods, such as croissants or brioches, may be kept uncovered at room temperature for a short time, or wrapped in plastic and frozen for longer storage. To reheat frozen bread, remove plastic and place the bread in a 350 degree oven for 10 minutes, or until the bread is thoroughly heated through. Serve warm, or cool it before serving.

Part of

Advertisement

Advertisement

The licensor does not allow printing of this title