Advertisement

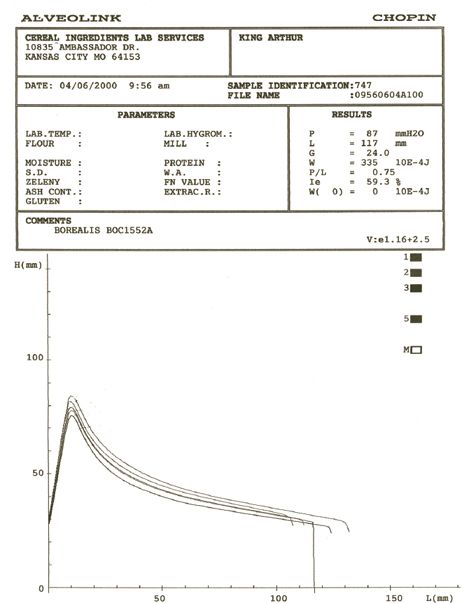

The Chopin Alveograph

Published 2004

The Chopin alveograph is another instrument used to measure the relative strength and baking ability of flour. It is the most common instrument used in Europe for flour testing, while in the United States it is much less frequently used, although it is gaining slowly in popularity. Interestingly, in the United States it is most often used by the cracker industry, where flour extensibility is highly important, as it indicates how thinly a cracker dough can be extruded.

Alveogram

The testing apparatus consists of a mixer, water jacketed to keep the dough at 24°C, that mixes an unyeasted dough for 7 minutes. The dough consists of 125 cubic centimeters of water salinated at 2.5 percent, and 250 grams of flour (this is the standard dough used by the American Association of Cereal Chemists, although in Europe flour and water quantities may be different). A sheeting mechanism extrudes the mixed dough onto a plate, where it is then literally blown into a bubble by air pumped from a diaphragm at a calibrated rate. Last of all, a recording device called a manometer measures the changes the dough bubble undergoes onto a chart. Each flour sample is mixed once, the tests are performed 5 times, and the average value is used to evaluate the flour. The purpose of this somewhat strange setup is to measure the dough’s resistance to rupturing as more and more air is blown into the bubble. Stronger doughs obviously can be blown up more than weaker ones before they pop, and different aspects of the test record various aspects of the dough’s deformation. Taken as a whole, the alveo-graph gives the baker a sense of the balance between the extensibility and elasticity of a dough made with a certain flour. Shows our sample. The figures are as follows: