Advertisement

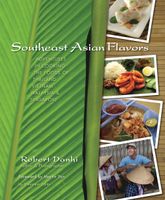

Rice Paper

Bánh Tráng

Appears in

By Robert Danhi

Published 2008

Rice paper, with its cross-hatched bamboo markings, has become one of the most utilized Vietnamese ingredients in Western kitchens. Cooks and chefs are finding all sorts of creative ways to fill them with nontraditional ingredients.

In Southeast Asia, rice paper is still often made using age-old traditional methods. (Some imported brands still buy these, but factory imitations are quickly filling the shelves.) As they’re made in Vietnam, a thin batter is prepared with pulverized whole rice (as described for rice noodles), water and salt. The soaked rice is added to the small hole on top as the entire round stone is rotated. As it moves downward, the rice paste through the stationary stone on the bottom and the top rotating stone and comes out very fine wet paste.