Advertisement

The Fourteen Steps of Bread Making

Selecting Ingredients

Even though there are only four basic ingredients—flour, salt, yeast, and water—in basic bread dough, there are many variations within those four that need to be considered. For instance, what type of flour is being used? What type of yeast—fresh, active dry, or instant dry? How coarse is the salt being used? What is the water temperature? Without answers to those questions, it will be difficult to achieve the desired result.

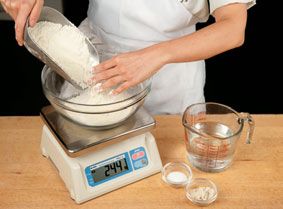

Scaling Ingredients

Accurate scaling (weighing), especially for the ratios of yeast and salt to flour, is crucial for effective fermentation. Inaccuracies will lead to less than desirable results. In bread making, all ingredients are scaled out by weight, not by volume.

Mixing

The mixing technique used and whether you incorporate an autolyse (a resting period during the mixing process) depends on the type of product you are making.

Bulk Fermentation

Bulk fermentation, the period during which the yeast produces carbon dioxide and alcohol and the dough’s gluten network continues to develop, can take anywhere from 10 minutes to overnight. The amount of time will be determined by the type of product you are making and the ratios in your formula.

Folding/Turning

Halfway through the bulk fermentation, almost all doughs are folded or turned. In home-style recipes for bread making, the process is often referred to as a punch. The fold/turn has four purposes. It strengthens the dough’s structure, evens out the temperature, redistributes and feeds the yeast by giving it access to new food (sugars), and aids in slowing down fermentation and the release of carbon dioxide in the dough.

Folding is done by first picking up and stretching the top side of the dough (while it is still in the bowl) and folding it toward the center. After the bowl is spun 180°, the top side is again stretched out and folded in. After a quarter turn of the bowl, the top is once again stretched out and folded in. The bowl is turned another 180° and, for the last time, the top is stretched out and folded in. Finally, the entire piece of dough is picked up and turned upside down into the bowl.

Dividing

The dough is divided immediately after the bulk fermentation is complete. A bench knife is used to divide the dough and a scale is used to confirm that each piece is the correct weight according to the formula.

Pre-shaping

Pre-shaping gives the baker the opportunity to set the structure of the final loaf and helps make the final shaping easier. The type of pre-shape depends on the final shape desired. Both bâtards and boules start with a round pre-shape, while a baguette is generally formed into a loglike pre-shape. All breads benefit from pre-shaping.

Bench Rest/Intermediate Fermentation

After pre-shaping, bread doughs must be rested so that the gluten network can relax before the final shape is formed. This is called a bench rest or intermediate fermentation and typically takes 15 to 20 minutes. The duration of the rest depends on the condition of the dough, the temperature and moisture levels of the bakery, and how tightly the baker has formed the pre-shape. A tighter pre-shape will take more time to relax than a looser one because the gluten structure is more elastic, and the baker will have to wait longer before final shaping.

Final Shaping

The final shape of the dough is determined by the type of finished loaf desired. In classic French bread making there are four basic shapes: the baguette, the bâtard, the boule, and the loaf (formed in a loaf-shaped pan).

Final Fermentation/Proofing

Although the yeast in bread dough has been working throughout the bread-making process, this is the last chance it has to complete the fermentation. The final proof can last anywhere from 5 minutes to overnight, depending upon the condition of the dough, the type of loaf being made, and temperature and moisture levels in the bakery.

Scoring

Scoring simply means cutting marks into the top of the dough to allow the bread to expand properly during baking. Although utilitarian, the marks also give a decorative appearance to the top of the baked bread. Most breads are scored just before they are loaded into the oven.

Baking

Baking time is determined by the type of dough being baked. Most lean doughs (doughs without fat or sugar) are baked at around 475°F (246°C) with steam. The steam is important, as it allows the bread to spring in the oven, giving it a shiny, crisp crust. Although they are lean, artisanal breads are usually baked for a longer period of time to develop the desired thick, crisp, and flavorful crust. Doneness is determined by the amount of time baked, the color of the crust, and the hollow sound that results when you knock on the bottom of the finished loaf.

Cooling

Bread cut directly upon removal from the oven will have a wet, spongy crumb and a gassy flavor from the carbon dioxide still present in the loaf. Therefore, bread should be cooled completely before being served or eaten. During the cooling period, the crumb is set and excess gas and moisture dissipate.

Storing

The shelf life of bread depends as much on its shape and size as it does on the type of bread and the manner in which it is stored. A small loaf or a loaf with an expansive surface (such as a baguette) has a very short shelf life, a day at most. Larger loaves can last longer if stored properly. Proper storage is crucial to maintaining both the quality of a bread and the loaf’s longevity. Breads that are meant to be crisp and crusty should not be stored in plastic or under refrigeration; a paper bag or a bread box is the best place to store these. Enriched bread may be stored in a resealable plastic bag, but when refrigerated these breads can become quite hard. Both lean and enriched breads usually last from 3 to 4 days at room temperature. If double-wrapped in plastic film so that it is airtight, most bread can be frozen for up to 3 months.