Advertisement

Repairing Failed or Broken Mayonnaise

Appears in

By Jaclyn Pestka, Wayne Gisslen and Lou Sackett

Published 2010

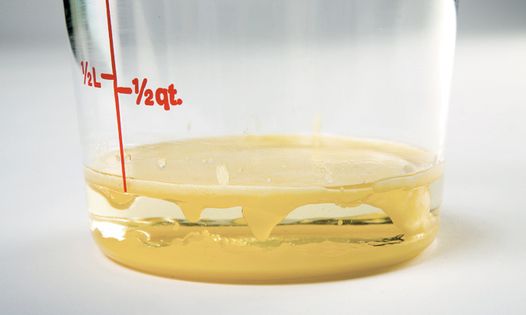

While a failed or broken mayonnaise can be frustrating, there is no need to throw it away. If the mayonnaise failed or broke due to temperature issues, first slowly bring the mayonnaise (and any repair ingredients) to 70°F (21°C) by letting it stand at room temperature. See Table 2.9 for steps to repairing mayonnaise.

Broken mayonnaise

Table 2.9

Method to Repair Failed or Broken Mayonnaise

Traditional Double-Batch Repair |

|

| Single-Batch Repair |

Allow the broken mayonnaise to stand until the oil separates from the yolk base. |

| Blender Repair |

|